Core Principles of Food Fermentation

What Is Fermentation

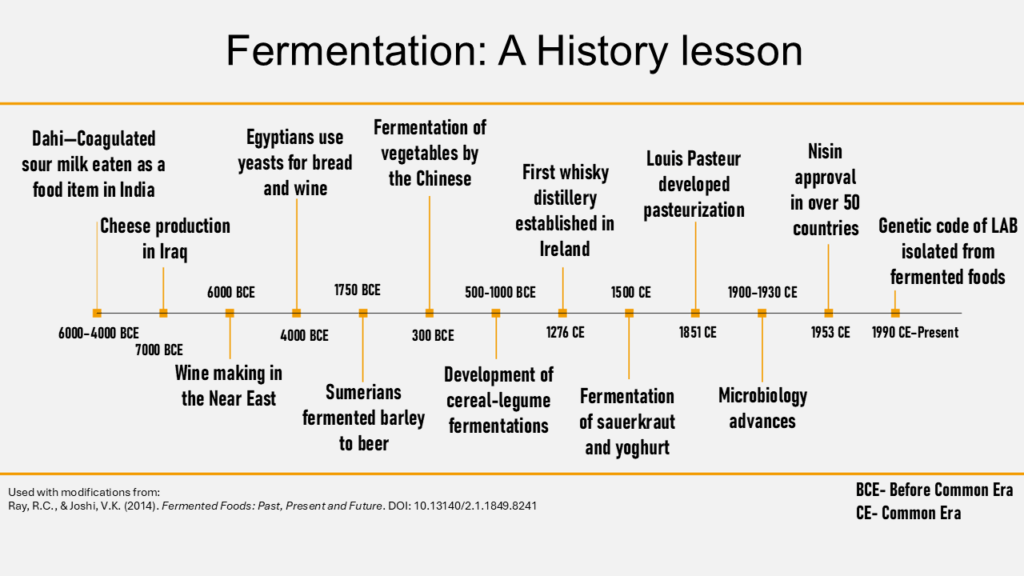

In this article I will try to explain some of the scientific principle and processes involved in fermentation. Interestingly, this process is older than humas species itself. In fact, it was and it’s an ongoing process even before the first human was born. It’s a recent a human discovering of the biotechnological tools that can harness the power of different microorganism for creating long lasting and delicious foods and drinks. With this knowledge human species can turn grapes into wine, milk into cheese and yogurt, grains into bread, among other foods. This discovery was likely a fortunate accident—someone left a piece of food, and after it fermented, they tried it and enjoyed it (1,2,3).

The principles behind the fermentation was not uncovered until the work of the Louis Pasteur. He discovered that specific organisms are behind this process and tried to give an explanation how it occurs (2,3). Today, with the advances of science, we know that fermentation is a complex biochemical process driven mainly by bacteria, yeasts, and fungi. Those microorganisms are using carbohydrates from raw materials as fuel. In general terms, fermentation is a biochemical process in which microorganisms break down available carbohydrates to produce energy under anaerobic (low-oxygen) or aerobic (with oxygen) conditions in a controlled manner. Interestingly, the global market for fermented foods is estimated at around USD 30 billion and continues to grow each year (6).

Why We Ferment?

We use fermentation for the benefits of the process- its adds value to fermentation in the following ways:

- Improves preservation by reducing the growth and survival of pathogenic microorganisms.

- Creates unique textures, aromas, and flavors.

- Enhances digestibility.

- Increases nutritional value.

- Supports gut health by producing probiotics.

Types and Methods of Fermentation

There are generally two starting methods used to achieve fermentation:

- Spontaneous fermentation (using native microflora):

This method relies on the fact that bacteria and yeasts are present on the surface of the raw materials. Examples include kimchi, sauerkraut, soy-based fermentation products, and sourdough. To archive this you will only need the right conditions—anaerobic environments and suppression of unwanted microflora using salt. - Starter culture fermentation (culture-dependent):

For some fermentations, a known and active culture of bacteria and/or yeast is intentionally added to the food to initiate the fermentation process. Those will include kefir, yogurt, kombucha, and natto.

Fermentation processes can also be categorized based on the main end products generated:

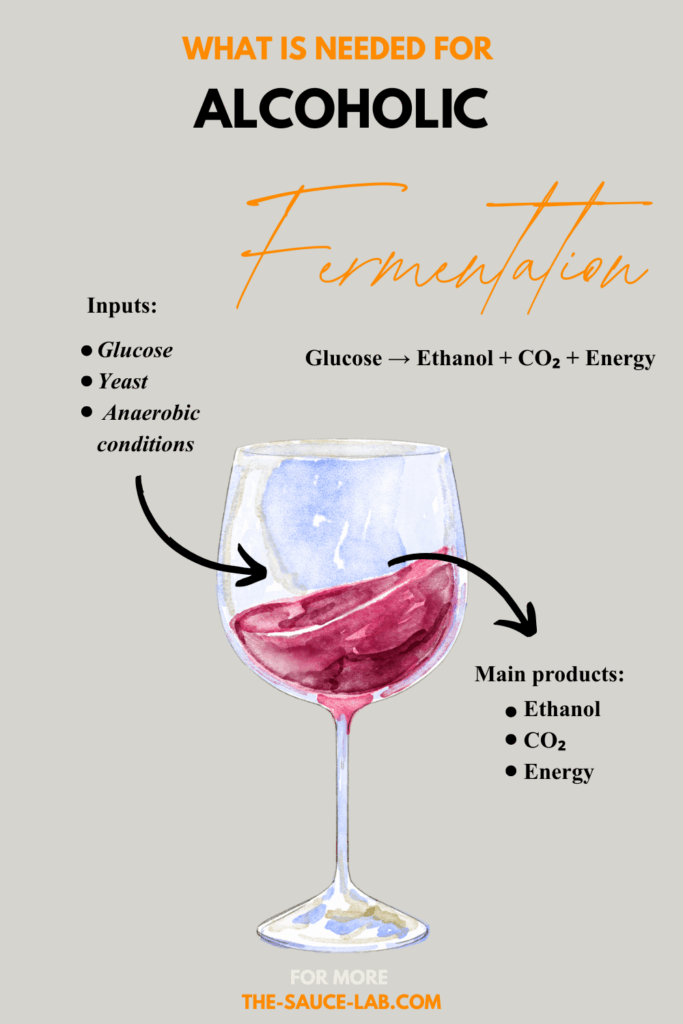

1. Alcohol Fermentation (Ethanolic Fermentation)

Main microorganisms: Saccharomyces cerevisiae (yeasts)

Main products: Alcohol (Ethanol) and Cabon dioxide (CO₂)

Examples:

- Beverages:

- Wine – fermented grapes

- Perry – fermented pears

- Cider – fermented apples

- Beer – fermented grains (usually barley)

- Mead – fermented honey

- Whiskey, vodka, rum, etc. – distilled from alcoholic fermentation products

- Foods:

- Sourdough bread – yeast produces CO₂ for leavening and ethanol (which evaporates during baking)

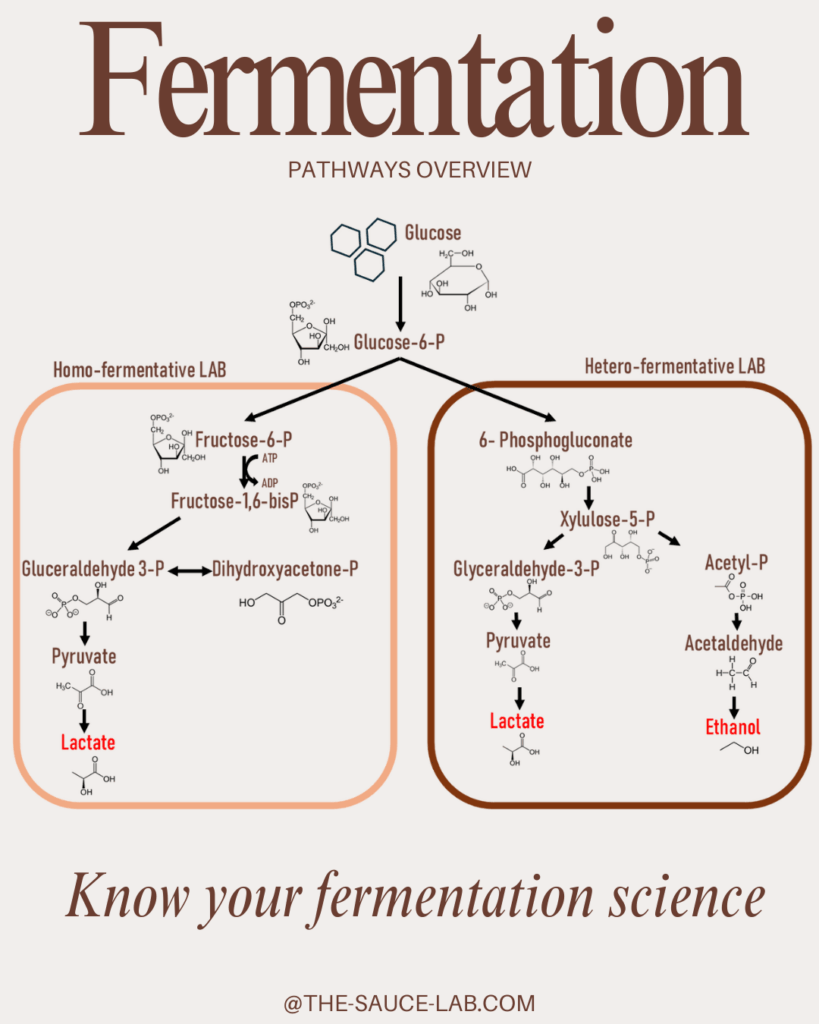

2. Lactic Acid Fermentation

Main microorganisms: Lactobacillus, Leuconostoc, Streptococcus, Lactococcus

Main product: Lactic acid

a. Homolactic Fermentation

- Produces mainly lactic acid

Examples:- Yogurt – Lactobacillus delbrueckii subsp. bulgaricus, Streptococcus thermophilus

- Kefir – lactic acid bacteria and yeasts (mixed but mainly lactic)

- Cheese – lactic acid bacteria during curd formation

b. Heterolactic Fermentation

- Produces lactic acid, ethanol, and CO₂

Examples:- Sauerkraut – Leuconostoc mesenteroides, Lactobacillus plantarum

- Kimchi – Leuconostoc, Lactobacillus species

- Soy sauce (partly) – involves lactic acid fermentation in later stages

- Kombucha (partly) – includes lactic acid bacteria along with yeasts and acetic acid bacteria

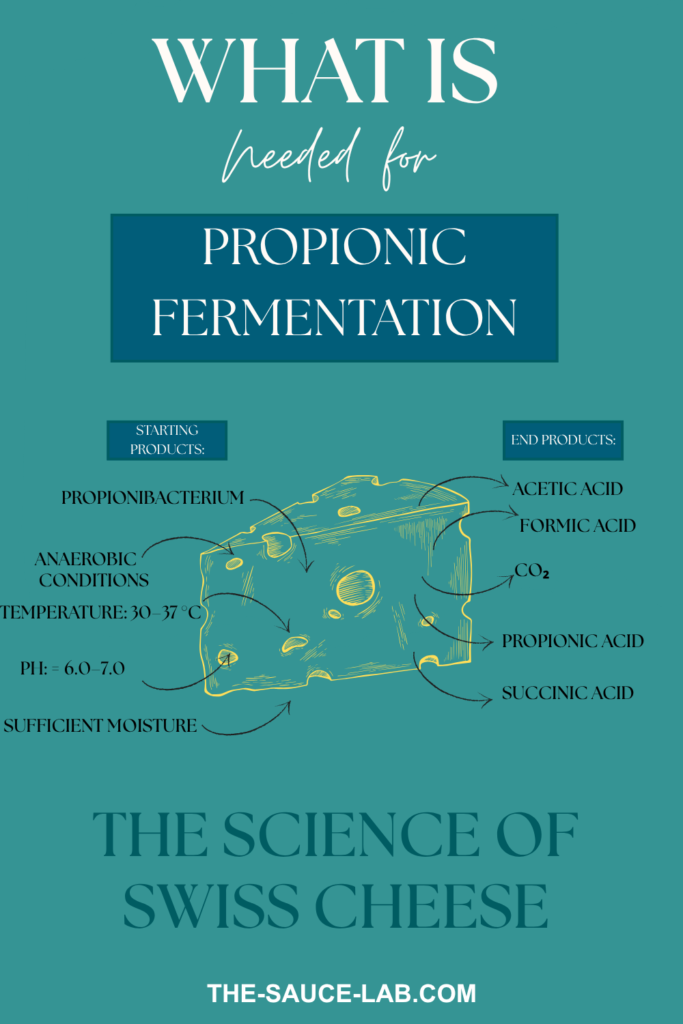

3. Propionic Acid Fermentation

Main microorganisms: Propionibacterium freudenreichii

Main products: Propionic acid, acetic acid, CO₂

Examples:

- Swiss-type cheeses (e.g., Emmental) – Propionibacterium converts lactic acid from earlier fermentation into propionic acid and CO₂, producing the nutty flavor and characteristic “holes.”

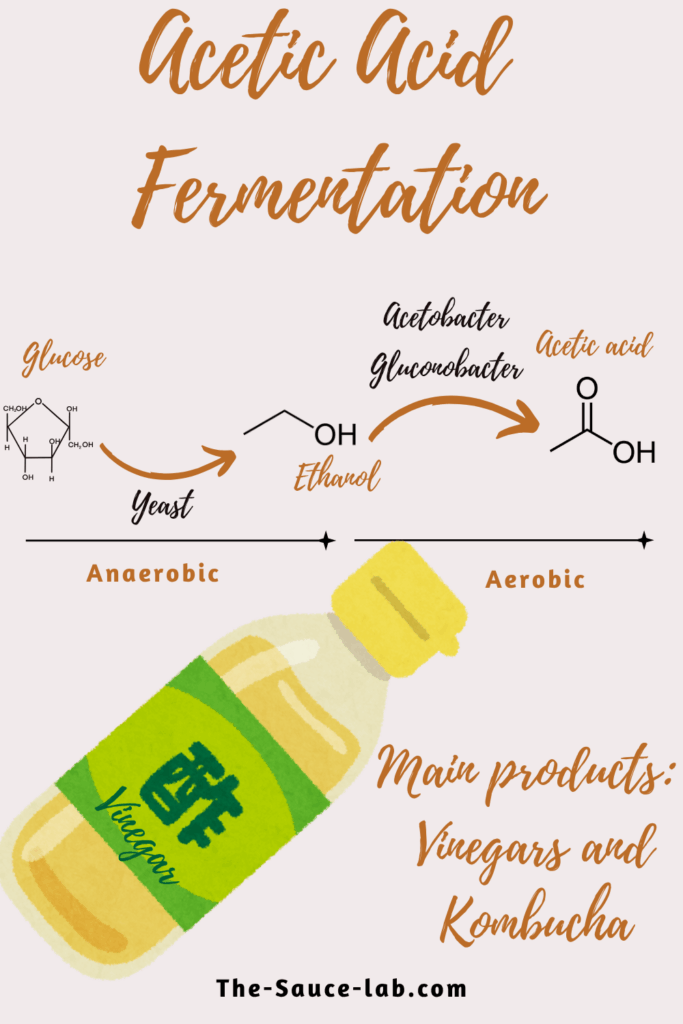

4. Acetic Acid Fermentation

Main microorganisms: Acetobacter, Gluconobacter

Main product: Acetic acid (from ethanol oxidation)

Examples:

- Vinegar – produced by oxidation of ethanol:

- Wine vinegar – from wine

- Apple cider vinegar – from cider

- Rice vinegar – from sake or rice wine

- Kombucha – acetic acid bacteria contribute to the sour taste

5. Butyric Acid Fermentation (Indicates Spoilage)

Main microorganisms: Clostridium butyricum, Clostridium pasteurianum

Main products: Butyric acid, CO₂, H₂

Examples:

- Not intentionally used in food fermentation (causes spoilage)

- Occurs undesirably in:

- Spoiled canned foods or silage

- Rancid butter (butyric acid causes foul odor)

6. Mixed Acid Fermentation (Indicates Spoilage)

Main microorganisms: Escherichia coli, Enterobacter, Salmonella, Shigella

Products: Lactic acid, acetic acid, succinic acid, ethanol, CO₂, H₂

Examples:

- Rarely used intentionally in food fermentation (often associated with spoilage)

- Can occur naturally in uncontrolled fermentation of some vegetables or meats

- Used experimentally in biofuel and organic acid production

Another way to classified different types of fermentations is according to the main organism involved: fungal, yeast, or bacterial fermentation.

During the process, specific metabolic products such as acetic acid, lactic acid, carbon dioxide, ethanol,and antimicrobial substances (e.g., hydrogen peroxide, bacteriocins) are produced. These metabolites contribute to extending the shelf life of fermented foods by inhibiting spoilage and the proliferation of pathogenic microorganisms. Some of them also contributes to the unique flavour and taste of the ferments.

General Conditions and Common Mistakes to Avoid

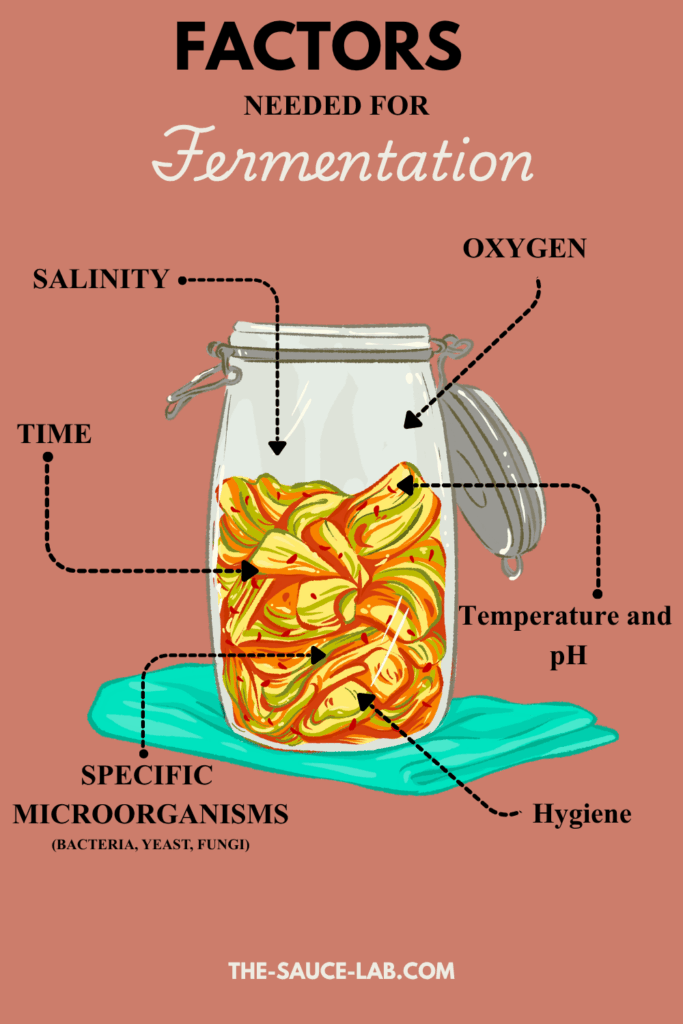

- Microorganisms and Substrate Selection

The correct microorganism works best with a specific raw material. Each organism has specific enzymes that determine the desired characteristics of the final product (e.g., Saccharomyces (yeast) for alcoholic fermentation, lactic acid bacteria for lactic fermentation). Most starting materials should contain carbohydrates—sugars, starches, or lactose (e.g., milk, vegetables, grains)—as an energy source for microbial growth and metabolism. - Temperature and pH

Microorganisms thrive within certain temperature and pH ranges. Generally, they prefer temperatures between 20–45 °C (68–113 °F). The process typically begins near neutral pH (6–7), but as acids such as lactic or acetic acid accumulate, pH decreases to around 3.5–5. - Oxygen Availability

The presence or absence of oxygen determines the metabolic pathway used by the microbes. For instance, acetic acid bacteria are strictly aerobic (require oxygen), while lactic acid bacteria are anaerobic (grow with little or no oxygen). - Time

Fermentation time varies depending on the food. Some vegetables ferment within 4–5 days, while others, such as sauerkraut, require several weeks to reach optimal flavor and stability. Proper timing ensures the accumulation of desired end products. - Salinity

A general salinity of 2–8% helps inhibit spoilage microorganisms while favoring the growth of lactic acid bacteria. - Sanitary Conditions

Fermentation equipment and the surrounding environment should be kept clean (though not sterile) to promote the dominance of desired microorganisms and prevent contamination.

Final thoughts

In summary, fermentation is still one of the oldest biotechnology processes in the world that was developed and employed by human beings. From ancient methods of preservation to modern interpretations, fermentation continues to combine tradition and science. Every ferment we do is continuing a story begun centuries ago — one that still simmers on peacefully in our research labs and kitchens around the world.

References:

1. Ray, R. C., & Joshi, V. K. (2014). Fermented foods: Past, present and future. https://doi.org/10.13140/2.1.1849.8241

2. Pasteur, L. (1879). Studies on fermentation: The diseases of beer, their causes, and the means of preventing them. Macmillan Publishers. (Landmarks of Science)

3. Pasteur, L. (1879). Physiological theory of fermentation. In Modern History Sourcebook: Louis Pasteur (1822–1895)

4. Voidarou, C., Antoniadou, M., Rozos, G., Tzora, A., Skoufos, I., Varzakas, T., Lagiou, A., & Bezirtzoglou, E. (2021). Fermentative foods: Microbiology, biochemistry, potential human health benefits and public health issues. Foods, 10(1), 69. https://doi.org/10.3390/foods10010069

5. Katz, S. E. (2012). The art of fermentation: An in-depth exploration of essential concepts and processes from around the world (Foreword by M. Pollan). Chelsea Green Publishing. ISBN: 9781603582865

6.Business Research Insights. (2025). Fermented foods market size, share & report [2033].