Food Waste to Flavour: Fermented Peel Spices

Introduction: What is Zero-Waste and Why It Matters

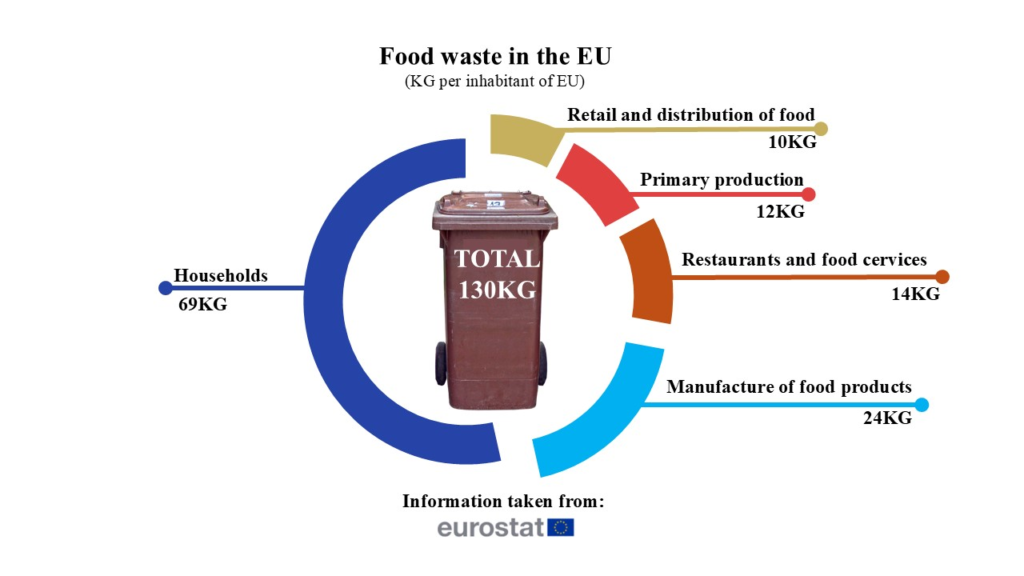

According to some estimates, around 58 million tonnes/year (130 billion lb/year) of food are wasted annually in the EU which is equivalent to food waste in the range of 130 kg per inhabitant (1). The statistic for the US shows similar numbers: 60.33 million tonnes/year (133 billion lb/year) of food waste annually. This means that the average EU citizen will waste food for about 200€ per person per year (2) and around $800 per person per year in the states (3). Those numbers are mindboggling.

Food can be defined as a bio-waste composed of raw or cooked food materials and includes food materials discarded at any time between it being purchased and consumed. It is the waste generated in a household before, during or after food preparation. An example will include scraps such as vegetable peelings, meat trimmings, spoiled or food that is left uneaten and tossed into the bin. In its essence the food waste can be either edible (e.g. apple or pear peels) or inedible (e.g. onion or garlic skins).

Even though you might think you produce inevitable waste, most of the leftovers from vegetables- their peels can be turned into all-purpose seasoning. Commercially available spices are way overpriced mixtures containing primary salt, additives and fillers. Instead, you can collect your trimmings and turn them into something that is aromatic, complex and sustainable- a Zero-Waste Fermented Spice.

Vegetables Suitable for Fermentation and Drying into a Spice

- Allium vegetables and their parts: onion skins, garlic skins, leek tops and trimmings

- Aromatic herbs and their parts: parsley stems, cilantro stems, celery leaves, celery stems, dill stems, basil leaves and stems, tarragon, mint, etc.

- Fruit parts and trimmings (high in sugars): apple peels, pear peels, grapes

- Vegetables high in glutamine: mushroom stems, dried mushroom trimmings

- Peppers parts and their trimmings: red bell pepper stems, pepper cores

- Root vegetable peels: carrot peels, parsnip peels, fennel trimmings, celeriac skin

- Citrus peels (without the white part; orange, lemon, lime, grapefruit): can be fermented or preserved in very high amounts of salt

Vegetables Not Suitable for Fermentation and Drying into a Spice

Not all vegetables are suitable for fermentation; some develop unpleasant flavors.

Bitterness

- Eggplant (aubergine) peel – ferment becomes very bitter

Too Sulfuric

- Radish peels (daikon, red radish)

- Turnip peels

- Kohlrabi peels

Too Fibrous or Woody

- Pumpkin or squash peels

- Sweet potato

- Corn and corn husks

- Thyme

- Rosemary

High Microbial Loads

- Potato peels – high soil microbial load; off aromas and bitterness

- Beetroot peels – high soil microbial load; off aromas and bitterness

Intense Chlorophyll or Grassy Notes

- Cucumber peels – too watery, bitter notes after fermentation

- Zucchini/courgette peels – watery, low flavor payoff

Peels High in Oxalates or Saponins

- Spinach stems – metallic notes after fermentation

- Pea pod skins – bitterness after fermentation

Peels That Ferment Too Fast → Slimy Textures

- Tomato skins – can ferment into sticky, gluey mass

- Melon and watermelon peels – ferment too rapidly due to high water + sugar

Important Safety Note: Peels, Pesticides, and Fermentation

Pesticides are chemical or biological agent that are used in the agriculture for the control of pests including herbicides, insecticides, fungicides, rodenticides etc. Those can act throughout contact and systemic way.

Certain degree of reduction of contact pesticides, such as trimming, peeling, washing and rinsing, soaking, blanching, boiling is quite effective (4).

It is important to know that even though here we are using peels, firstly we have washed them throughout multiple times and secondly fermentation on itself is an effective way of reducing or in some cases eliminating the residual pesticides from the vegetables or fruits (4,5). The actual reduction depends on the pesticide’s chemical stability, type, penetration, microbial activity during fermentation, and the fermentation time.

If you want, you can also use organic produce– it most probably contains far less pesticides that regular grown vegetables and fruits (4,5).

Why Bother with Fermenting Peels?

Kitchen trimmings and scraps as those listed contain a wide range of aromatic molecule, polyphenols sugars and amino acids. During fermentation the yeasts and LAB (Lactic Acid Bacteria) will ingest simple building block molecules like carbohydrates, protein and lipids form the fermenting products and contribute to the production of various metabolites. Those substances will be converted subsequently into aromatic compound mixture, which will give the final fermented product its flavour characteristics (6,7). Furthermore, the intensity of those flavour compounds will increase after dehydration, capturing it in the form of powdered zero-waste all-purpose spice.

Because I’m a home cook, I don’t generate large amounts of peel on day-to-day bases. For this experiment I collected trimmings and refrigerated them until I have at least 500g (17.6 oz) of products.

How to Use Your Zero-Waste Fermented Spice

- In bread dough or focaccia — mix a little bit into the dough or sprinkle on top before baking.

- Popcorn seasoning — Mix a little bit on top of hot popcorn

- Ideal for tofu and meat — Dry rub or marinade this spice will add complexity to any meat, vegetable or tofu without the need for additional aromatics.

- Homemade compound butter — blend into softened butter → perfect for finishing dishes.

- Umami sauce —dissolve the spice in a brown stock and reduce to create an umami bomb. It will be perfect for complementing stakes and grilled vegetables.

Ingredients for This Recipe

- Vegetable peels and scraps – X amount

- Bottled water – Z amount

- Salt – Y amount

- Yogurt – 20g (0.71 oz)

How to Calculate Salt Percentage

For a 3% brine (multiply by 0.03):

(Vegetables + Water) = X + Z

Salt needed: (X + Z) × 0.03 = Y grams of salt

This same calculation will be applied to products and salt concentration when you use the Imperial and US customary measurement systems.

Step-by-Step Recipe for Zero-Waste Spice

- When you peel or trim something, freeze it as soon as possible.

- Once you have enough, thaw them.

- Rinse the collected peels throughout with agitation

- Soak them in water for 2 to 4 hours. Agitate every hour or so. After agitation change the water. This helps to remove dirt and pesticide residue.

- Drain the peels well.

- Place your fermenting jar on a kitchen scale and put them inside. Pour enough water so every part is fully submerged.

- Calculate how much salt is needed. For example, I decided to do 3% salt:

• 2594g (water + vegetable peels) x 0.03 = 77.82 g of salt.

• 91.49 oz (water + vegetable peels) × 0.03 = 2.74 oz of salt. - Measure the calculated amount of salt.

- Pour a small amount of water that you have measured into a small glass, add the salt and stir until it dissolves

- Add the dissolved salt back into the jar

- Add 20g of yogurt and stir.

- Put a weight on top of the vegetables so everything is submerged under water.

Tip: If you don’t have fermentation weights, use parchment paper and wooden skewers to keep everything submerged. - Ferment (incubate) for at least 7 days at room temperature

- Drain the water from the vegetable peels and squeeze the excess moisture.

Note: The leftover liquid can be used for another fermentation projects.

- Blend the peels so that the pieces become smaller— this will speed up the dehydration process.

- Place the blended peels in a dehydrator or oven at 50-70°C (122–158°F)

Note: I used 60°C/140.0 °F)

- Stir them from time to time. This will ensure faster and even drying.

- Dehydrate them until they are completely dry.

- Blend them in a food processor until they are powder

- Enjoy your Zero-Waste spice blend

Storage

- Store in dark, airtight container in a cool, dry place away from direct sunlight.

- Check regularly: It is advisable to check the spice periodically for any signs of mold or clumping, which indicates excess moisture.

- Moldy spices: In the case where you find mold in your spice, discard the batch, as it’s not safe to eat.

The Science Behind This Spice

Freezing = Cell Rupture + Increased Substrate Availability

Since most of the trimmings have relatively high-water content, if you freeze them in a regular house-hold freezer ice crystal formation will occur. Those ice crystals will pierce and damage the plant cell walls, which will inevitably increase the enzymes, amino acids, carbohydrates once thawed. From these two possibilities can occur: either the scraps will become extremely mushy during and after fermentation or it will make their cellular content (proteins, lipids, carbs) more accessible to LABs and microbial action leading to better fermentation and better flavour profile.

Freezing = Cell Rupture + Death of LABs and Yeasts

Even though some scientific papers show that some bacteria can survive freezing, and even repeated freeze-thawing cycles. It should be noted that some of the researchers use a solution of glucose which is a known cryopreservative and a rapid freezing technique, which is very difficult to replicate in home conditions. So, I decided to seed the fermentation and increase the chances for it to happen. I gave it a push by adding a little bit of Bulgarian yogurt. It should contain Lactobacillus delbrueckii subsp. Bulgaricus and Streptococcus thermophilus, which will introduce a reliable population of Lactic Acid Bacteria (LABs) into the fermentation system.

Fermentation = Flavor and Umami Development

As we have previously seen, LABs can metabolize sugars converting them into lactic acid (reduces the pH and gives of some tanginess on the tongue), acetic acid (contribute to tanginess and piquant flavour), and some leftover bioactive peptides and peptides short chains of amino acids (see the footnote) (elevates the umami).

This mixture was left to ferment for 7 days, during which LABs were able to convert the sugar into acid, lowering the pH, stabilizing the environment and creating the new aromatic compounds.1

Drying = Concentration of Volatiles + (possible)Mild Maillard Reactions

After 7 days I decided it’s time to end the fermentation, so the scraps were drained, shredded and dried. The drying procedure was done in an oven with the drying settings turned on (fan on low heat = 60°C/140.0 °F). At this temperature presence of Maillard– type of reaction will most probably not occur (at this speed you need at least a few months for the reaction to occur). For this batch it took nearly 48h to completely dry. Ensuring that there is no moisture left will preventing mold contamination.

Grinding = Release of Aromatics + Controlled Mouthfeel

The final step was to blend the spice into fine powder. This will increase the surface area and increase the volatile compound that were trapped in the dehydrated plant tissue.

The Final Product: A Zero-Waste Spice Rich in Fermented Complexity

Through freezing, fermentation driven by LABs, dehydration, and grinding, ordinary waste products such as vegetable peels were converted into a complex, aromatic all-purpose spice blend with depth as good as store-bought traditional seasoning powders. Each step discussed will contribute to the flavour of the final product:

- Freezing: cell rupture → increased substrate access

- Fermentation: acidification, umami release, aroma compound formation

- Drying: concentration of volatile molecules

- Grinding: liberation of aromatics + uniform mouthfeel

The result is a sustainable seasoning, demonstrating how zero-waste methods can produce flavours that are both scientifically fascinating and gastronomically powerful.

Zero-Waste Fermented Spice: Transforming Vegetable Peels Into Aromatic Spice

Ingredients

Method

- When you have vegatable scraps like peels and trimings freeze them as soon as you prep them.

- Once you have enough, thaw them.

- Rinse them throughout with agitation.

- Soak them in water for 2 to 4 hours. Agitate every hour or so. After agitation change the water.

- Drain the peels well.

- Place your fermenting jar on a kitchen scale and put them inside. Pour enough water so every part is fully submerged.

- Calculate and measure the amount of salt that is needed. (Formula in the main text).

- Pour a small amount of water that you have measured into a small glass, add the salt and stir until it dissolves.

- Add 20g of yogurt and stir. Add them both into the jar.

- Put a weight on top of the vegetables so everything is submerged under water.

- Ferment (incubate) for at least 7 days at room temperature.

- Drain the water from the vegetable peels and squeeze the excess moisture.

- Blend the peels so that the pieces become smaller— this will speed up the dehydration process.

- Place the blended peels in a dehydrator or oven at 50-70°C (122–158°F).

- Stir them from time to time. This will ensure faster and even drying.

- Dehydrate them until they are completely dry.

- Blend them in a food processor until they are powder.

- Enjoy your Zero-Waste spice blend.

References

- Home – Eurostat

- Food Safety – European Commission

- Food Waste Solutions & Statistics – Reducing Food Waste in the U.S.

- Chung, S. W. C. (2017). Journal of the Science of Food and Agriculture, 98(8), 2857–2867.

- Armenova, N., et al. (2023). Foods, 12(6), 1163.

- Zhang, K., et al. (2023). Current Research in Food Science, 6, 100405.

- van Wyk, N. (2024). Foods, 13(5), 730.

- ● Amino Acid– The fundamental monomer or “building block” of proteins.

● Peptide– A short chain of amino acids linked by peptide bonds. (Dipeptides: 2 amino acids or Oligopeptides: up to ~20 amino acids)

● Polypeptide– A long, continuous chain of amino acids, generally considered to be 20–50 or more amino acids in length.

● Protein– A functional molecule made of one or more polypeptides that have folded into a specific three-dimensional structure. ↩︎